| Performance | Travel Speed (High/Low) | 3 / 2 km/h |

|---|---|---|

| Ground Pressure | 48.6 kPa | |

| Machine Dimension and Weight | Machine Weight | 12,150 kg |

| Overall Length (Folded) | 8,950 (8,420) mm | |

| Overall Width | 2,600 mm | |

| Overall Height | 2,730 mm | |

| Minimum Ground Clearance | 480 mm | |

| Crawler Width | 600 mm | |

| Transport Dimension | Overall Length for Transportation | 8,420 mm |

| Overall Height for Transportation | 2,730 mm | |

| Discharge Conveyor Dimension | Conveyor Length | 3,300 mm ± 250mm |

| Conveyor Width | 600 mm | |

| Conveyor Setting Height | 2,600 mm ± 200mm | |

| Tub Dimension | Opening Diameter (Outside/Inside) | 2,350 / 1,800 mm |

| Tub Depth | 1,300 mm | |

| Engine | Name | CAT C7.1 |

| Nominal Output | 151 kW / 2,200 rpm | |

| Fuel Used | Diesel | |

| Tank Capacity | Fuel Tank Capacity | 280 ℓ |

| Hydraulic Oil Tank Capacity | 180 ℓ | |

| DEF Tank Capacity | 32 ℓ | |

| Off-Road Law Emission Regulation Notification and Standards | Name and Model of The non-road special motor vehicle | MOROOKA MC-2000-VA |

| Name and Type of Specified prime mover | Caterpillar YDS-C7.1-IND | |

| Emission Standard | Tier 4 Final / EU Stage IV |

| Performance | Travel Speed (High/Low) | 1.9 / 1.2mph |

|---|---|---|

| Ground Pressure | 7psi | |

| Machine Dimension and Weight | Machine Weight | 26,786lbs |

| Overall Length (Folded) | 29’4″ (27’7″) | |

| Overall Width | 8’6″ | |

| Overall Height | 8’11” | |

| Minimum Ground Clearance | 19″ | |

| Crawler Width | 24″ | |

| Transport Dimension | Overall Length for Transportation | 27’7″ |

| Overall Height for Transportation | 8’11” | |

| Discharge Conveyor Dimension | Conveyor Length | 10’10″± 10″ |

| Conveyor Width | 24″ | |

| Conveyor Setting Height | 8’6″± 8″ | |

| Tub Dimension | Opening Diameter (Outside/Inside) | 7’9″ / 5’11” |

| Tub Depth | 4’3″ | |

| Engine | Name | CAT C7.1 |

| Nominal Output | 205 HP / 2,200 rpm | |

| Fuel Used | Diesel | |

| Tank Capacity | Fuel Tank Capacity | 74 gal (US) |

| Hydraulic Oil Tank Capacity | 47.6 gal (US) | |

| DEF Tank Capacity | 8.5 gal (US) | |

| Off-Road Law Emission Regulation Notification and Standards | Name and Model of The non-road special motor vehicle | MOROOKA MC-2000-VA |

| Name and Type of Specified prime mover | Caterpillar YDS-C7.1-IND | |

| Emission Standard | Tier 4 Final / EU Stage IV |

Downloads SPEC SHEET DOWNLOAD

Feature

Strong undercarriage and high driving performance

Thick-walled, seamless rubber crawler is a masterpiece of outstanding durability, using 40 years of experience and know-how since its development! The HST (Hydro Static Transmission) system drives the rubber crawlers. The hydraulic drive transmission system ensures smooth movement. As it is a compact and self-propelled machine equipped with rubber crawlers, it can be driven directly to the work site.

Tub grinder that enables the crushing of a large amount of lumbers, branches, and leaves!

The tub grinder, which feeds from above, can be used for lumbers of uneven thickness, hardwoods with trunks that are not straight, thick trunks close to the roots, large volumes of lumbera, and branches and leaves.

“Automatic reversing function”

If the cutter drive pressure or speed reduction rate exceeds a set value during crushing, the tub automatically reverses to prevent material jams. This function allows the smooth crushing of material.

Equipped with “the magnetic separator”

The magnet separator sorts and removes metals, such as nails, mixed in on the discharge conveyor. It prevents foreign materials from mixing into the generated chips.

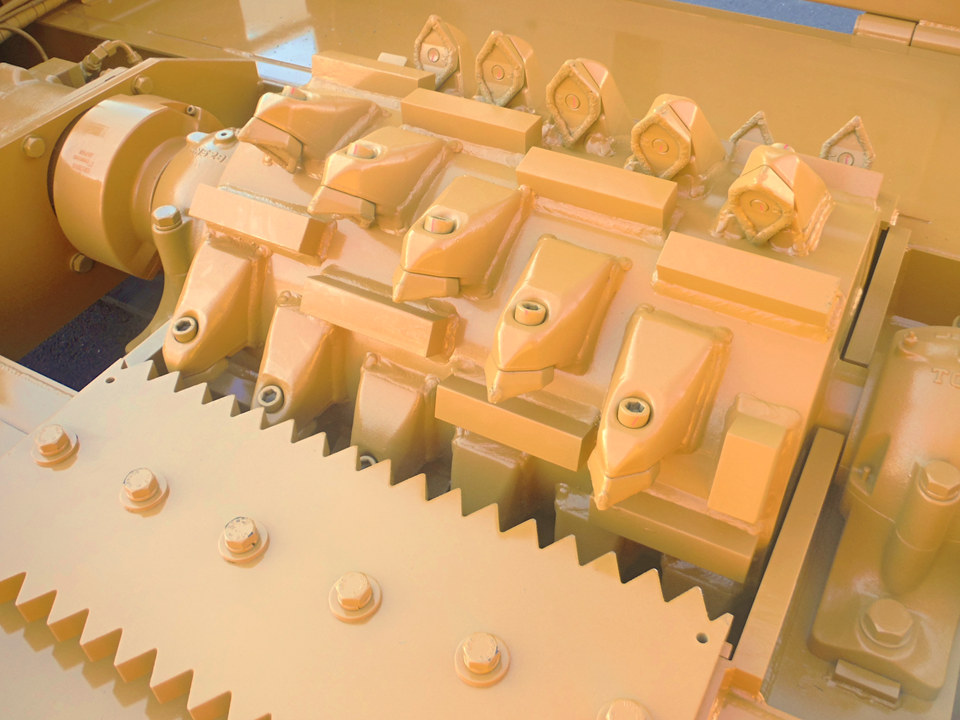

Selectable crushing blades and screens

Crushing blades and screens can be selected by several types according to the size and shape of the material you want to generate.

Maintenance

Improved maintainability

Each equipment is arranged for efficient servicing and maintenance. The structure is designed for smooth inspection and maintenance.

The tub can be opened and closed 90° for easy maintenance, such as the replacement of screens and cutter blades and cleaning work.

The tub can be opened and closed 90° for easy maintenance, such as the replacement of screens and cutter blades and cleaning work.

Lower running costs

If the cutter blade and receiving blade wear out, they can be used repeatedly by replacing the top and bottom or the reverse side, which leads to lower running costs.

<Cutter blade > Can be used twice in total by replacing the top and bottom blades.

<Receiving blade> Can be used four times in total by replacing the top and bottom blades and the front and back blades.

<Cutter blade > Can be used twice in total by replacing the top and bottom blades.

<Receiving blade> Can be used four times in total by replacing the top and bottom blades and the front and back blades.

Safety

“Emergency stop switch”

Emergency stop switches are equipped at three locations on the driver’s seat and the left and right sides of the machine to stop all crushing, running, and other movements in an emergency.