| Performance | Maximum Payload | 4,800 kg |

|---|---|---|

| Travel Speed (High/Low) | 10.2 / 7.1 km | |

| Ground Pressure (Empty/Laden) | 30.3 / 46.3 kPa | |

| Machine Dimension and Weight | Operating Weight | 9,100 kg |

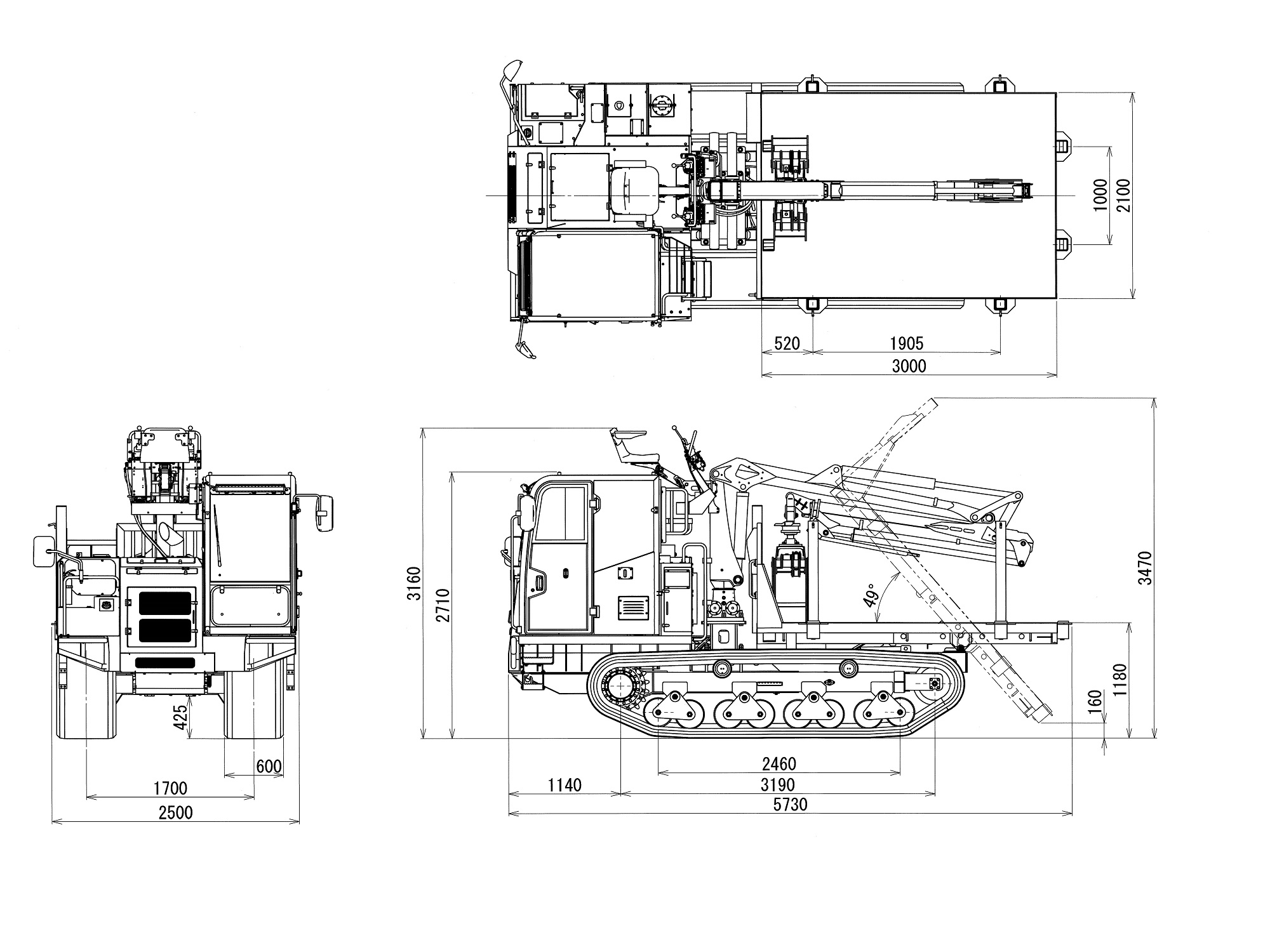

| Overall Length | 5,730 mm | |

| Overall Width | 2,500 mm | |

| Overall Height | 3,160 mm | |

| Minimum Ground Clearance | 425 mm | |

| Crawler Width | 600 mm | |

| Crawler Outer Width | – | |

| Dump Body | Dump Shape | Flat Bed |

| Length x Width | 3,000 x 2,100 mm | |

| Grapple | Name | Cranab FC45DT |

| Grapple Capacity | 300 kg x 8 m | |

| Engine | Name | Caterpillar C4.4 |

| Nominal Output | 92.6 kW / 2,200 rpm | |

| Fuel Used | Fuel | Diesel |

| Fuel Tank Capacity | 127ℓ | |

| Tank Capacity | Hydraulic Oil Tank Capacity | 54ℓ |

| DEF Tank Capacity | 19ℓ | |

| Off-Road Law Emission Regulation Notification and Standards | Model Name of Non-road Special Vehicle | MOROOKA MST-1000VDLG |

| Type Name of Specified prime mover | Caterpillar YDR-C4.4ND-IND | |

| Emission Standard | Tier 4 Final / EU Stage IV |

| Performance | Maximum Payload | 10,582 lbs |

|---|---|---|

| Travel Speed (High/Low) | 6.3 / 4.4 mph | |

| Ground Pressure (Empty/Laden) | 4.4 / 6.7 Psi | |

| Machine Dimension and Weight | Operating Weight | 20,062 lbs |

| Overall Length | 18’10” | |

| Overall Width | 8’2″ | |

| Overall Height | 10’4″ | |

| Minimum Ground Clearance | 17″ | |

| Crawler Width | 24″ | |

| Crawler Outer Width | – | |

| Dump Body | Dump Shape | Flat Bed |

| Length x Width | 9’10” x 6’11” | |

| Grapple | Name | Cranab FC45DT |

| Grapple Capacity | 661 lbs x 26’3″ | |

| Engine | Name | Caterpillar C4.4 |

| Nominal Output | 126 HP / 2,200 rpm | |

| Fuel Used | Fuel | Diesel |

| Fuel Tank Capacity | 33.6 gal(US) | |

| Tank Capacity | Hydraulic Oil Tank Capacity | 14.3 gal(US) |

| DEF Tank Capacity | 5 gal(US) | |

| Off-Road Law Emission Regulation Notification and Standards | Model Name of Non-road Special Vehicle | MOROOKA MST-1000VDLG |

| Type Name of Specified prime mover | Caterpillar YDR-C4.4ND-IND | |

| Emission Standard | Tier 4 Final / EU Stage IV |

Dimensions

unit:mm

Downloads SPEC SHEET DOWNLOAD

Feature

Strong undercarriage and high driving performance

The thick-walled, seamless rubber crawler is a masterpiece of outstanding durability, using 40 years of experience and know-how since its development! The HST (Hydro Static Transmission) system drives the rubber crawlers. The hydraulic drive transmission system ensures smooth movement.

Warning lamps and LCD monitor are centrally located on the right side of the operator’s seat.

Warning lamps and the LCD monitor are located centrally on the right side of the operator’s s seat. Various statuses related to the vehicle such as remaining fuel level, voltage, engine speed meter, warning lamp lighting, etc. can now be easily checked.

Equipped with wear-resistant steel plate “HARDOX®” dump bed

The dump bed adopted HARDOX®, a wear-resistant steel plate that can withstand long-term use at forestry sites, for improved durability. It features a long service life and low running costs.

Electronic travel lever

The conventional hydraulic pilot-type traveling lever changed to an electronically traveling lever. Electronic control supports driving and realizes smooth and comfortable operation. In addition, the improved layout of the traveling lever provides more legroom and improved comfort.

“Auto-decel function” and “HST speed mode”

The Auto-decel function lowers the engine speed automatically when idling continues for a certain period of time to improve fuel economy and reduce CO₂ emissions and noise.

In addition to it, operators can select vehicle speed from three different speed modes. This allows not only high-speed driving but also stable driving at low speeds.

Cranab FC45DT grapple

MST-1000VDLG is equipped with a grapple.

・The maximum reach is 8m, which enables pulling lumbers over a wide area.

・Two stage telescopic arm

・The maximum reach is 8m, which enables pulling lumbers over a wide area.

・Two stage telescopic arm

*When equipped with a grapple, the maximum loading capacity becomes 4,800kg.

Maintenance

Improved maintainability

All equipment is arranged for efficient servicing and maintenance. An open/close air conditioner condenser and a foldable oil cooler structure are incorporated. Removable dust net in front of the radiator improves cleanability.

Safety

Fulfilled safety function

By pressing the emergency stop button, the vehicle engine can be stopped in case of emergency.

The engine cannot start unless turned ON the parking brake. This function prevents unintended operation after the engine starts.

The engine cannot start unless turned ON the parking brake. This function prevents unintended operation after the engine starts.

Equipment for safe working

Reinforced protective bumpers on both sides of the front of the vehicle, which are safe and durable in the tough job sites and are easy to remove, are standard.

Large LED head lights above the cabin can work safer in nighttime and dark places.

Large LED head lights above the cabin can work safer in nighttime and dark places.