| Performance | Maximum Payload | 7,000 kg |

|---|---|---|

| Travel Speed (High/Low) | 9.6 / 6.7 km | |

| Ground Pressure (Empty/Laden) | 25.6 / 43.9 kPa | |

| Machine Dimension and Weight | Operating Weight | 10,900 kg |

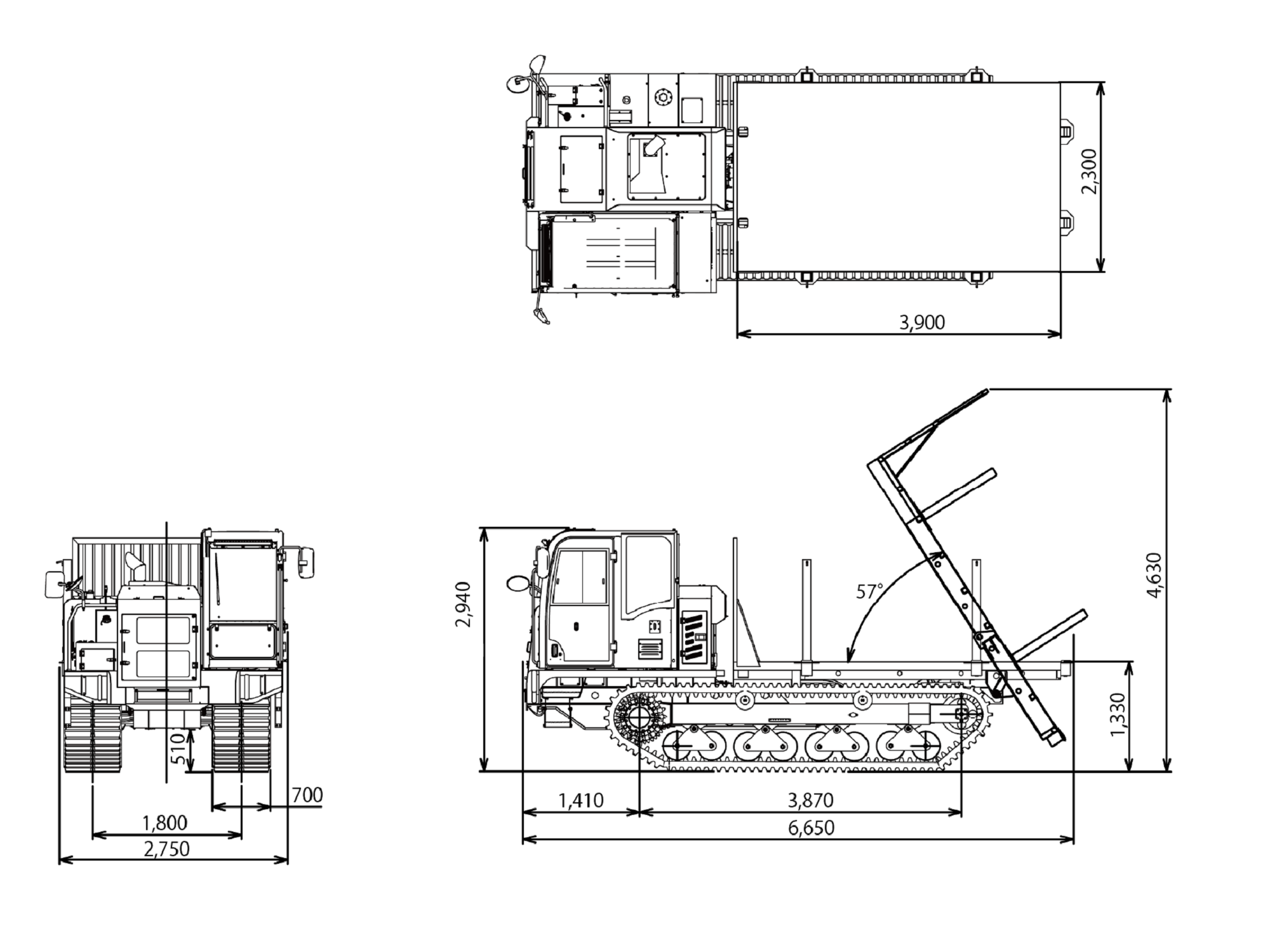

| Overall Length | 6,650 mm | |

| Overall Width | 2,750 mm | |

| Overall Height | 2,940 mm | |

| Minimum Ground Clearance | 510 mm | |

| Crawler Width | 700 mm | |

| Crawler Outer Width | – | |

| Dump Body | Dump Shape | Flat Bed |

| Length x Width | 3,900 x 2,300 mm | |

| Grapple | Name | – |

| Grapple Capacity | – | |

| Engine | Name | Cummins QSB6.7 |

| Nominal Output | 168 kW / 2,200 rpm | |

| Fuel Used | Fuel | Diesel |

| Fuel Tank Capacity | 200ℓ | |

| Tank Capacity | Hydraulic Oil Tank Capacity | 100ℓ |

| DEF Tank Capacity | 19ℓ | |

| Off-Road Law Emission Regulation Notification and Standards | Model Name of Non-road Special Vehicle | MOROOKA MST-1500VDL-VB |

| Type Name of Specified prime mover | Cummins QSB6.7-4C | |

| Emission Standard | Tier 4 Final / EU Stage IV |

| Performance | Maximum Payload | 15,432 lbs |

|---|---|---|

| Travel Speed (High/Low) | 6 / 4.2 mph | |

| Ground Pressure (Empty/Laden) | 3.7 / 6.4 Psi | |

| Machine Dimension and Weight | Operating Weight | 24,030 lbs |

| Overall Length | 21’10” | |

| Overall Width | 9’0″ | |

| Overall Height | 9’8″ | |

| Minimum Ground Clearance | 20″ | |

| Crawler Width | 28″ | |

| Crawler Outer Width | – | |

| Dump Body | Dump Shape | Flat Bed |

| Length x Width | 12’10” x 7’7″ | |

| Grapple | Name | – |

| Grapple Capacity | – | |

| Engine | Name | Cummins QSB6.7 |

| Nominal Output | 228 HP / 2,200 rpm | |

| Fuel Used | Fuel | Diesel |

| Fuel Tank Capacity | 52.8 gal(US) | |

| Tank Capacity | Hydraulic Oil Tank Capacity | 26.4 gal(US) |

| DEF Tank Capacity | 5 gal(US) | |

| Off-Road Law Emission Regulation Notification and Standards | Model Name of Non-road Special Vehicle | MOROOKA MST-1500VDL-VB |

| Type Name of Specified prime mover | Cummins QSB6.7-4C | |

| Emission Standard | Tier 4 Final / EU Stage IV |

Dimensions

unit:mm

Downloads SPEC SHEET DOWNLOAD

Feature

Strong undercarriage and high driving performance

The thick-walled, seamless rubber crawler is a masterpiece of outstanding durability, using 40 years of experience and know-how since its development! The HST (Hydro Static Transmission) system drives the rubber crawlers. The hydraulic drive transmission system ensures smooth movement.

Warning lamps and LCD monitor are centrally located on the right side of the operator’s seat.

Warning lamps and the LCD monitor are located centrally on the right side of the operator’s s seat. Various statuses related to the vehicle such as remaining fuel level, voltage, engine speed meter, warning lamp lighting, etc. can now be easily checked.

Equipped with wear-resistant steel plate “HARDOX®” dump bed

The dump bed adopted HARDOX®, a wear-resistant steel plate that can withstand long-term use at forestry sites, for improved durability. It features a long service life and low running costs.

Hydraulic pilot type 2 levers

A hydraulic pilot-type travel lever is adopted. This travel lever reduces the burden on the operator during operation and provides excellent responsiveness and fine operability.

Maintenance

Improved maintainability

Each equipment is arranged for efficient servicing and maintenance. The large opening front grille is designed for smooth inspection and maintenance.

Safety

Fulfilled safety function

By pressing the emergency stop button, the vehicle engine can be stopped in case of emergency.

The engine cannot start unless turned ON the parking brake. This function prevents unintended operation after the engine starts.

The engine cannot start unless turned ON the parking brake. This function prevents unintended operation after the engine starts.

Equipment for safe working

Reinforced protective bumpers on both sides of the front of the vehicle, which are safe and durable in the tough job sites and are easy to remove, are standard. Reinforced ribbed undercover protects the machine from rough road thrust.

Large LED head lights above the cabin can work safer in nighttime and dark places.

A large mirror is adopted to check the safety of the surrounding area, which is often a blind from the operator’s seat to enhance safety during work.

Large LED head lights above the cabin can work safer in nighttime and dark places.

A large mirror is adopted to check the safety of the surrounding area, which is often a blind from the operator’s seat to enhance safety during work.

Reliable forestry-specific design

The frame, designed specifically for the forestry industry, maintains the optimum weight balance when loading logs. It improves stability when transporting lumbers.