| Performance | Maximum Payload | 8,000 kg |

|---|---|---|

| Travel Speed (High/Low) | 10.6 / 7.4 km/h | |

| Ground Pressure (Empty/Loaded) | 27.9 / 46.6 kPa | |

| Machine Dimension and Weight | Operating Weight | 11,950 kg |

| Overall Length | 5,750 mm | |

| Overall Width | 2,665 mm | |

| Overall Height | 3100 mm | |

| Minimum Ground Clearance | 560 mm | |

| Crawler Width | 700 mm | |

| Dump Body | Dump Shape | Scoop End |

| Length x Width x Height | 2,400 x 2,350 x 545 mm | |

| Dump Capacity (Struck/Heaped) | 2.4 / 4 m³ | |

| Engine | Name | KUBOTA V5009 |

| Nominal Output | 151.9 kW / 2,200rpm | |

| Fuel Used | Diesel | |

| Tank Capacity | Fuel Tank Capacity | 210 ℓ |

| Hydraulic Oil Tank Capacity | 106 ℓ | |

| DEF Tank Capacity | 40 ℓ | |

| Off-Road Law Emission Regulation Notification and Standards | Name and Model of The non-road special motor vehicle | MOROOKA MST-1500VDR-ⅥD |

| Name and Type of Specified prime mover | KUBOTA V5009-CR-VTI-YDS-2 | |

| Emission Standard | Tier 4 Final / EU Stage V |

| Performance | Maximum Payload | 17,637 lbs |

|---|---|---|

| Travel Speed (High/Low) | 6.6/4.6 mph | |

| Ground Pressure (Empty/Loaded) | 4/6.8 psi | |

| Machine Dimension and Weight | Operating Weight | 26,345 lbs |

| Overall Length | 18’10” | |

| Overall Width | 8’9″ | |

| Overall Height | 10’2″ | |

| Minimum Ground Clearance | 22″ | |

| Crawler Width | 28″ | |

| Dump Body | Dump Shape | Scoop End |

| Length x Width x Height | 7’10” x 7’9″ x 1’9″ | |

| Dump Capacity (Struck/Heaped) | 3.1 / 5.2 yd³ | |

| Engine | Name | KUBOTA V5009 |

| Nominal Output | 207 HP / 2,200 rpm | |

| Fuel Used | Diesel | |

| Tank Capacity | Fuel Tank Capacity | 55.5 gal (US) |

| Hydraulic Oil Tank Capacity | 28 gal (US) | |

| DEF Tank Capacity | 10.6 gal (US) | |

| Off-Road Law Emission Regulation Notification and Standards | Name and Model of The non-road special motor vehicle | MOROOKA MST-1500VDR-ⅥD |

| Name and Type of Specified prime mover | KUBOTA V5009-CR-VTI-YDS-2 | |

| Emission Standard | Tier 4 Final / EU Stage V |

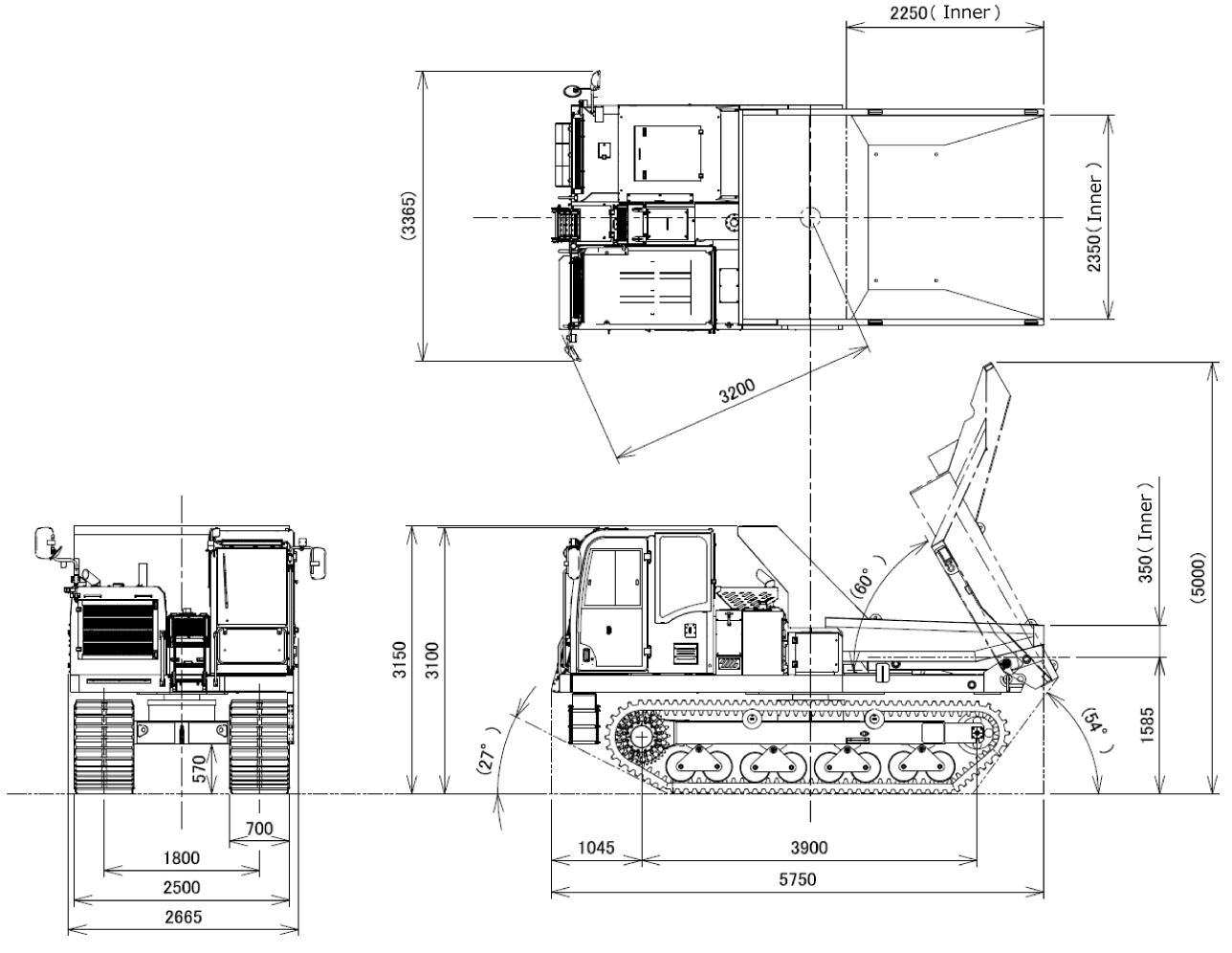

Dimensions

unit:mm

Downloads SPEC SHEET DOWNLOAD

Feature

360° Full Rotating Crawler Carrier

360° Full Rotating Crawler Carrier

The machine could change travel direction at narrow space without pivot turn and spin turn since upper structure can rotate. The rotating function also eases the machine to unload.

The machine could change travel direction at narrow space without pivot turn and spin turn since upper structure can rotate. The rotating function also eases the machine to unload.

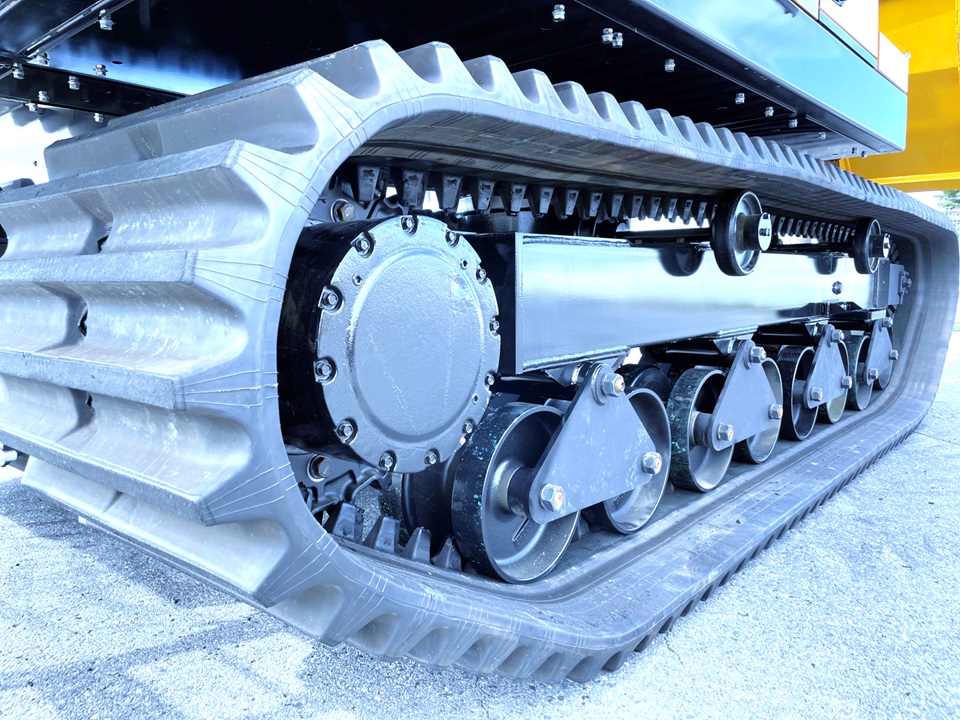

High performance movement and excellent traction

Thick, seamless rubber tracks provide outstanding durability! The rubber crawler is driven by The HST (Hydro Static Transmission) system. Hydraulic drive transmission provides smooth movement.

Caution lamps and monitor display have been centralized at right hand side of operator seat.

Caution lamps and monitor display have been centralized at right hand side of operator seat. machine status including amount of fuel, voltage, engine rotation, caution lamp lighting when problem occurs can be easily checked.

Hardox® In My Body certified dump body has been applied

Newly applied Hardox® In My Body certified dump body improves durability of the dump bed and also contributes running cost reduction due to its longer life than conventional tipping body.

Electric Control Joystick

Electric control travel lever has been introduced. Intuitive operation is possible with only the left-hand joystick for driving. Driving posture has also been improved compared to conventional machines, reducing operator’s fatigue. In addition, operation systems such as the horn and high speed/low speed switching are integrated into the travel lever, allowing the vehicle to travel as the operator wishes.

Auto Decel function and super slow mode

The “Auto Decel function” automatically lowers the engine speed when idling for a certain period of time, improving fuel efficiency and reducing CO2 emissions and noise.

Super slow mode is an excellent mode for slow speed operation. You can drive with confidence in situations that require slow speeds such as driving on narrow roads, loading work to transport vehicles, and parking.

Maintenance

Improvement in maintainability

The front grille which has a large opening, making it easy to perform inspections and maintenance. DEF tank is placed next to the fuel tank for added convenience.

Large sized step

The step used to climb up and down the vehicle during inspection and maintenance has been improved.

Renewed dump bed lock system

The lock mechanism on the dump bed stopper has been redesigned for quick and safe access.

Safety

ROPS / FOPS Cabin

The cabin with great comfort and visibility is compatible with ROPS (Rollover Protection Structure) and FOPS (Falling Object Protective Structure) to protect the operator.

Safety functions

You can stop the vehicle’s engine by pressing the emergency stop switch.

The engine does not start unless the parking brake is turned on, preventing unintended operation after the engine starts.

A safety lock lever is equipped on left side of the seat. By installing a safety lock lever in addition to the parking brake, safety is greatly improved and accidents caused by unintended movements are prevented.

Enhanced safety functions

A rear-view camera is equipped so that the operator can check the safety of the surrounding area, which is likely to be a blind spot, from the operator seat. It increases safety at work.

A large LED headlight is placed on the upper part of the cabin, making it safer to work at night or in dark places.

Equipped with a large mirror so that you can check the safety of the surroundings, which are likely to be blind spots, from the driver’s seat.